Overview

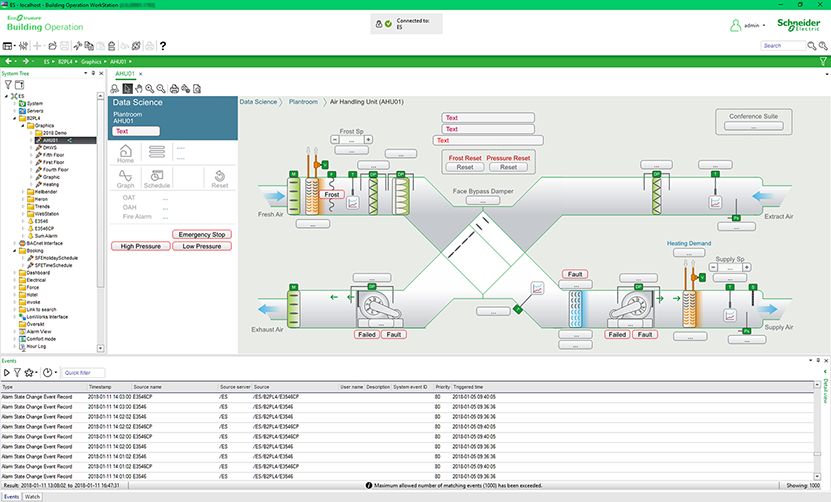

Background InformationAs a regional energy and sustainability engineer at Sodexo Healthcare, one of my main responsibilities is to manage the performance of the building assets within one of the biggest healthcare sites in the UK - Central Manchester Hospital.

This would include utilizing my knowledge and expertise in predictive maintenance techniques along with utilizing an FDD software (Xempla) in order to transform our maintenance services from a schedule-based to a conditional-based program and reduce downtime and failure to prevent risk to patients safety and also any commercial liabilities. In addition, ensure that all the assets are operating within their acceptable range and their energy consumptions are closely monitored to ensure system compliance.

Case Study

Below are two real cases from AHU 1 and AHU 2 regarding how by creating automatic workflows through our FDD software we were able to pinpoint deviations in performance which would would've led to total unit failure.

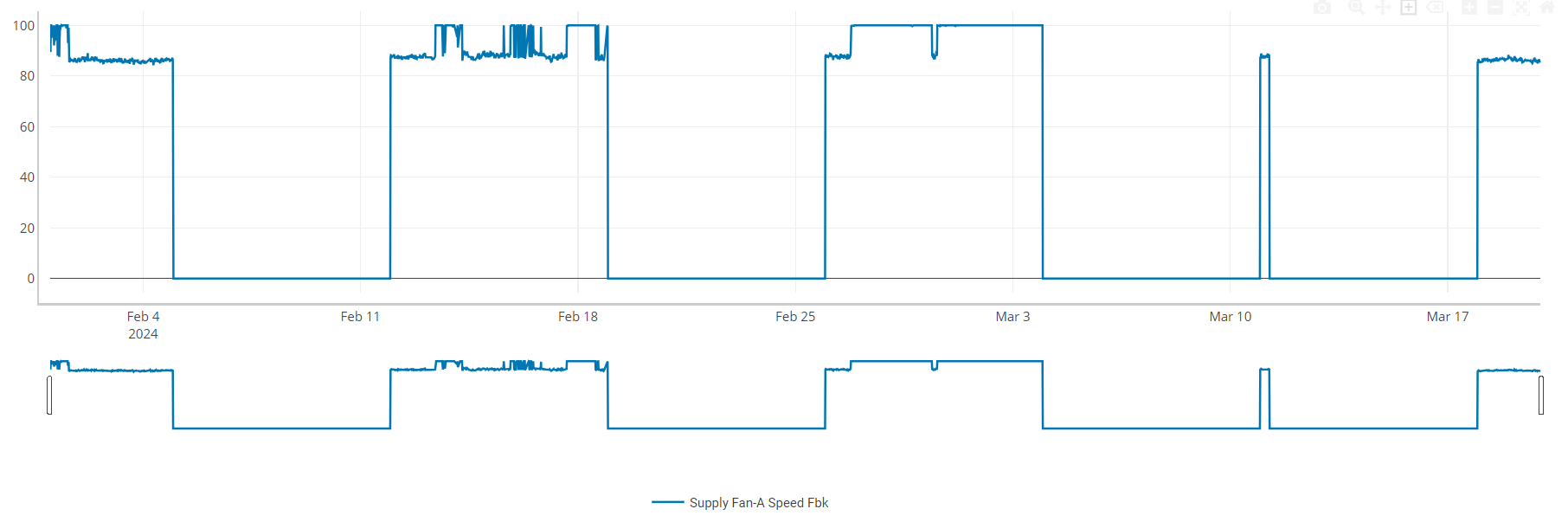

Air Handeling Unit 1:

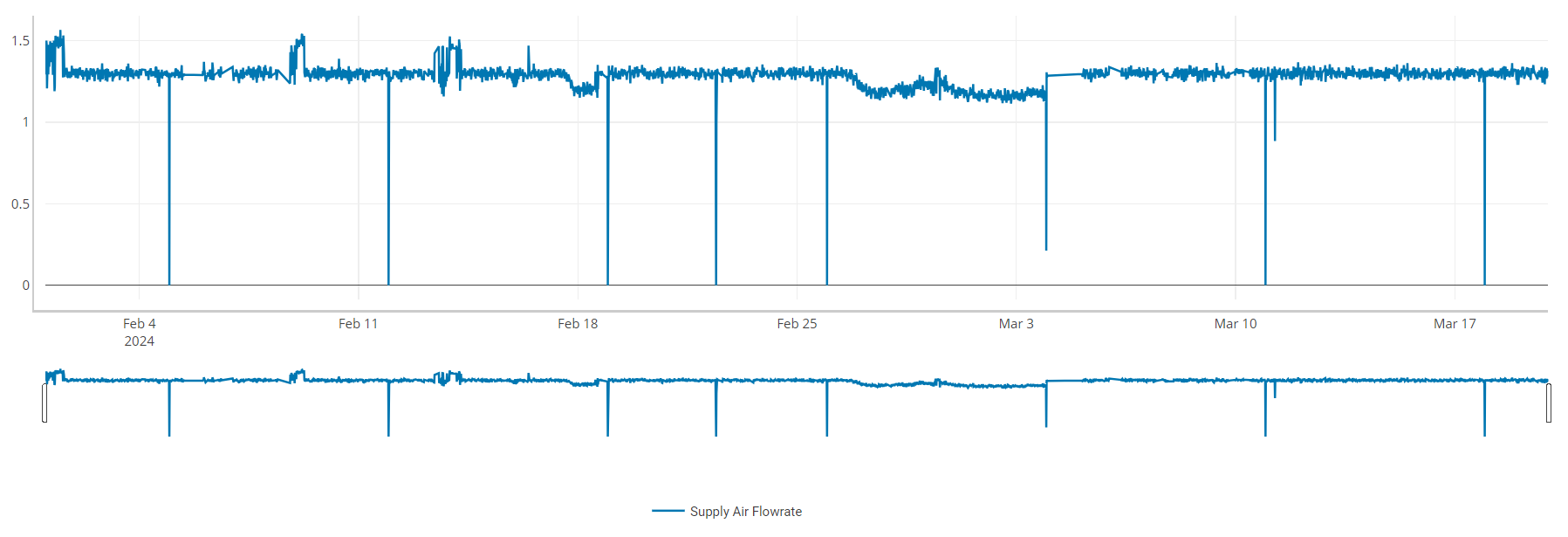

Supply Fan has jumped in speed suddenly while the pressure and flow readings show reductions in readings compared to previously. This triggered a corrective job request to be raised which actually turned out to be a slipping drive belt. By replacing the belt before it failed, we've prevented a risk of downtime.

Outcome:After attending to the AHU, it seems that the drivetrain belt connecting the motor and the fan pulley is loose and is losing traction resulting in power losses. This caused the fan VFD to speed up to max speed in order to try and comply with the drop in air flowrate which can be seen to drop.

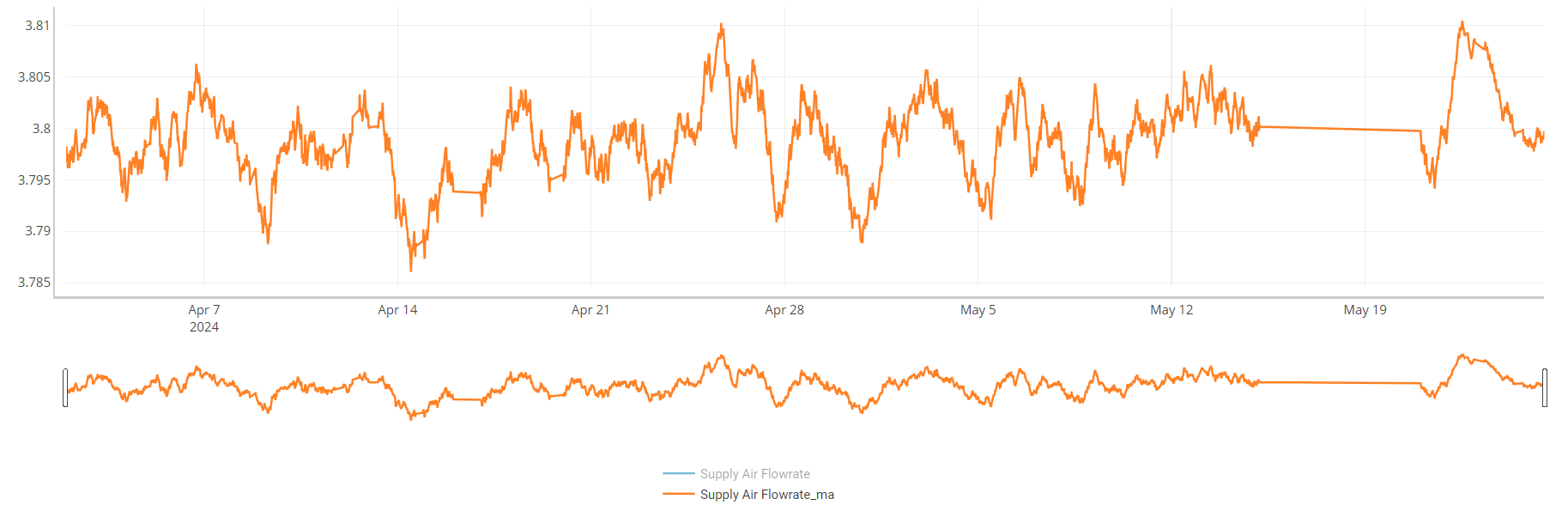

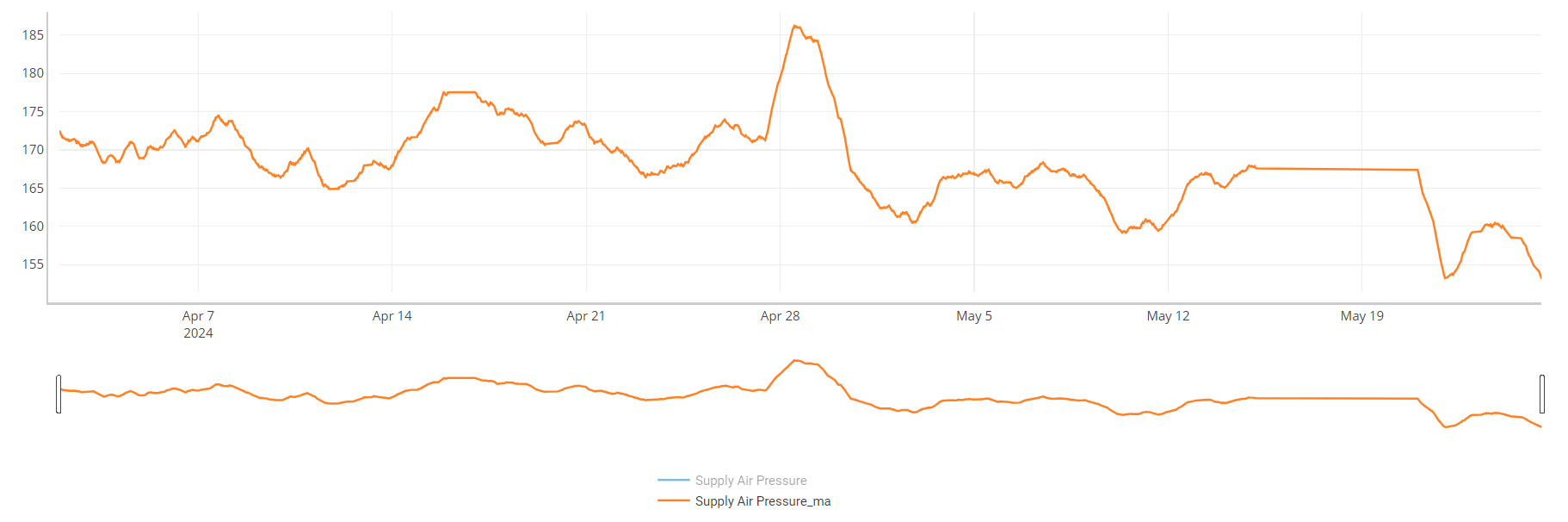

Air Handeling Unit 2:

In this case, it can be seen from the trends that the fan speed and pressure readings dropped excessively while the airflow reading remained almost constant. The result of the raised job request was a collapsed filter panels which is critical in conditioning the air being supplied to the hopsital.

Outcome:In this case, we've determined an issue where the unit suffered a collapsed filter which wouldn't have been determined until the next planned preventative maintenance scheduled which will increase the air contaminants being supplied to hospital areas.

Benefits:

Energy:

1.3 MWh of energy saved so far allowing us to reduce the load on our electrical infrastructure.

Carbon Emissions:

252,102 CO2e has been prevented

Corrective Actions:

200+ corrective actions were taken as result of our analysis, allowing us to realize the benefits stated above.

Project Photos

.png)